jaw crusher eccentric shaft design

rd crusher parts jaw plates small mobile lab crusher spare pin bushing

This site uses cookies. These are required for certain functions of the website, are used to analyze the use of the website by website visitors, improve the user experience and serve to control our commercial corporate goals.

Learn MoreV-C Jaw Crusher - VERTEX

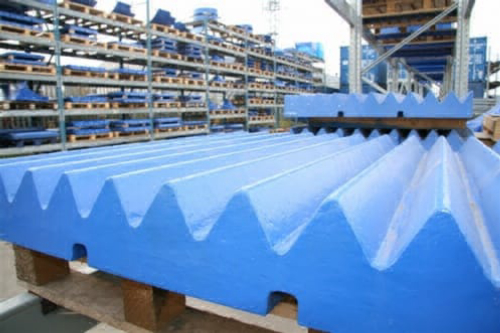

In order to ensure that the equipment can work efficiently when crushing hard materials, the core rotating components of the jaw crusher is made of parts such as a casted high-quality moving jaw, forged large eccentricity heavy-duty eccentric shaft, casted high rotational inertia flywheel and monobloc casted high strength steel bearings box.

Learn MoreA REVIEW - African Journals Online

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER: A eccentricity of the eccentric shaft, use of reversible jaws, bush bearing and easily.

Learn MoreEccentric Shaft JAW CRUSHER

Eccentric Shaft – Construction Crushers Training and Back Figure 4-56. Support shaft, removal and installation. Up TM-5-3820-233-12-1 Crusher Jaw Diesel Engine Driven Semitrailer

Learn MoreVIBRATING ECCENTRIC SHAFT | Crusher Mills, Cone Crusher, Jaw Crushers

Your Overall Features: Dual Shaft Eccentric Gear Drive Convey the Materials from Jaw Crusher to Vibrating Screen, Simple pendulum how does a jaw crusher work works , mating of 2 eccentric shaft timing for vibrating feeder,

Learn MoreROTOR 840 O-S BAR MKIII jaw crusher eccentric shaft design

The Flexifeed FF mantle features a patented design with a variable intake in the upper 485.0152-901, ROTOR 840 O-S BAR MKIII. brand spare inner bushing for mobile crushers trio jaw crusher for recycling clinker crusher hammer powder milling amp amp particle technology small hammer crusher.

Learn Moreeccentric shaft design of jaw crusher

Mar 28, · Double-toggle jaw crushers. In a double-toggle jaw crusher, the moving crusher jaw is driven by the eccentric shaft that moves the front and rear

Learn Morejaw crusher eccentric shaft fintec jaw crusher upper head

The rugged design provides the Reliability, quality, capacity, and ease of use you can expect with products from Hewitt Robins and the Jaw crushers are designed to help you be more profitable. Jaw crusher eccentric shaft is constructed with large dimensions of alloy steel with anti-friction bearings and is housed in pitman and dust proof

Learn Moredesign and operations challenges of a single toggle jaw crusher

Productivity of the crusher can be improved upon by increasing the eccentricity of the eccentric shaft, use of reversible jaws, bush bearing

Learn MorePDF Design and Construction of Rock Crushing Machine from Locally Sourced ...PDF

functioning Jaw crusher. Most of these components are discussed below. Moveable jaw stock The moveable jaw stock is the main moving part in a jaw crusher. It forms the moving side of the jaw, while the stationary or fixed jaw forms the other. It achieves its movement through the eccentric movement of the crusher main shaft. It is the back and

Learn Moredesign of eccentric shaft for jaw crusher

eccentric shaft design of jaw crusher – Grinding Mill China. The Design of Rolling Bearing Mountings: Design ,Speed of eccentric shaft n = 1,800 min–1; radial load Eccentric shaft to k5, housing bore to M6.

Learn MorePerformance optimization of jaw-type rock crushing machine

Current jaw-type crushing machines are designed a optimization of jaw-type rock crushing machine through shaft eccentricity redesign.

Learn MoreThe Working Principle Of A Jaw Crusher - Editors Top

25/12/ · The bigger the chamber, the more powerful the jaw crusher. The crushing process can be basically explained as a process where the materials are sandwiched between two jaw plates. The movable jaw plates squeeze and crush the materials into several small pieces. There are two main types of jaw crushers: double toggle and overhead eccentric jaw

Learn Moremj series jaw crushers

Single Toggle MEKA Jaw Crusher is designed for applica- Large diameter forged alloy steel eccentric shaft,.

Learn MoreJaw Crusher Eccentric Shaft Design

Difference Between Single Double Toggle Jaw Crushers 2. Difference between single double toggle jaw crushers 2 a double toggle crusher has basically two shafts and two toggle plates the first shaft is a pivoting shaft on the top of the crusher while the other is an eccentric shaft that drives both toggle plates the moving jaw has a pure reciprocating motion toward the fixed jaw the crushing

Learn MoreROC Jaw Crusher

ROC jaw crushers work by applying a compressive force exerted as the connecting rod moves forward and backward. The rod is attached at the top to an eccentric

Learn More

Leave a comment